Non Woven

Opening Blending and Nonwoven from LAROCHE S.A. Belgium

LAROCHE, world leader in equipment for processing fibres, in technologies for recycling and nonwovens, was established in 1926.

Opening Blending and Nonwoven

In the field of nonwovens, LAROCHE offers very accurate opening and blending lines. LAROCHE has developed since the nineties airlaying machines too producing at low cost

firts quality felts for Mattress felts (bedding), furniture, carpet underlay, horticulture, insulation, automotive, geotextile, filtration, hygiene and wipes.

The Airlay machine is designed to handle all types of fibres - short re-cycled to long and coarse natural fibres (even glass fibres). This machine produces mat from 200 gr/m2 upto 3000/4000 gr/m2

(according to fibres) having width upto 4000 mts.

Lines of products

Lines of products

Machines

Machines

Log on to:

www.laroche.fr

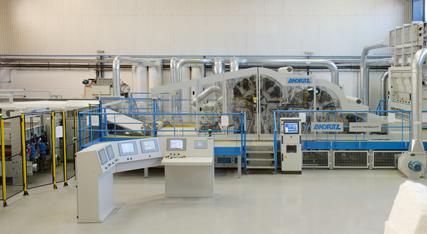

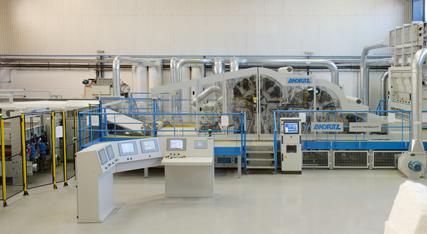

ANDRITZ Asselin-Thibeau

www.andritz.com/oi-andritz-asselin-thibeau-sas

Specialist for drylaid nonwovens machines and lines for direct or crosslaid technologies applicable to all kinds of bonding processes

ANDRITZ Asselin-Thibeau, located in Elbeuf, Belgium, has united the expertise of two pioneers in nonwovens drylaid processes, Antoine Thibeau & Cie (founded in 1896) and Asselin Cie, (founded in 1920). Both companies have been leading providers of customized system solutions for the textile and nonwovens industries right from the very beginning.

Core competences

Today, ANDRITZ Asselin-Thibeau designs and manufactures integrated production lines that include inline and/or crosslaid carding, spunlace, needlepunch, and thermal, chemical, or through-air bonding. All lines can be equipped with a supervisory control assistance system, including production recipes. The product portfolio includes equipment for several levels of performance, depending on local market size, fabric weight, production speed, final application, and maintenance requirements. Brands like eXcelle, aXcess, or ProDyn have set a worldwide benchmark for quality and ensure that customers always find exactly the right technology for their individual demands.

Research and development

The nonwovens market is characterized by a multitude of constantly changing applications. ANDRITZ Asselin-Thibeau therefore has a clear focus on continuous research and development. One example of a recent development in inline carding is the Isoweb TT card. The special configuration at the card output provides remarkable enhancements in CD tensile values and closer MD/CD ratios at very high production speeds. Also in crosslaid carding, innovative devices like ACS and Ouat!sys, which allow crosslapper feeding at higher speed, provide best productivity and optimized quality of the fabric at the same time. Our on-going efforts concentrate on easy-to-apply systems that ensure user-friendly operation and utmost cost efficiency in nonwovens production.

Product development in our technical centers

ANDRITZ Asselin-Thibeau focuses on designing customized solutions.

We offer an unrivalled technical center, providing trials, product development, marketing tests, training, and support are for the following technologies:

- Carding

- Crosslapping

- Drafting

- Needlepunching

- Winding

Global presence

Thanks to the global network of the ANDRITZ GROUP, ANDRITZ Asselin-Thibeau has the international presence to provide full and effective support to our customers and partners.

QINGDAO JINZUAN NEEDLES CO. LTD

Qingdao Jinzuan Needles Co. Ltd. is the largest and most important producer of felting and structuring needles for the nonwoven industry in China. They also manufacture fittings such as brushes for velour production.

Almost 30 years of production and constant quality and technology improvement have made their needles a crucial key for the extraordinary development of the nonwoven industry in China and is supporting as well needlepunch fabric manufacturers in a growing number of countries worldwide. They hold patents for several self-developed technologies.

The needles count with 11 categories, which comprises TAPER, TRINGULAR, San Yan, DIAMOND, CYLINDER, STAR, SPIRAL, CROWN, FORK, LONG POINT, INVERTED BARB NEEDLES. They have needles for every single application geotextiles, filtration, carpets, artificial leather, automotive fabrics etc.

If they don't have the needle for any particular needs, they simply create it specially for the customer. Also they have excellent performance-price ratio keeping manufacture costs low while maintaining high efficiency and product quality.

CROWN NEEDLE

INVERTED BARB NEEDLE

INVERTED BARB NEEDLE

Card Clothing for Nonwoven sector - Bekaert Carding Solutions, Belgium

Deeco with Bekaert Carding Solutions, Belgium

-

They are world leaders in their field & very well known

-

Deeco is with Bekaert Carding Solutions since 2001.

-

The product range which Deeco deals with Bekaert is Card Clothing for long staple & Nonwovens

Company Profile

Bekaert Carding Solutions at your service

A wide range of carding wires with excellent performance looking for the best carding solution

for your specific long staple and non-woven application? Bekaert might be just the reliable

partner you are looking for.

Through partnerships with textile machine builders and customers world wide Bekaert strives to

be the independent and recognized leader in the card clothing business. By enabling our

customers to benefit from our know-how, technological strengths and operational excellence, we

believe that we can deliver you carding solutions that are truly unique.

The Bekaert group is a European based company, headquartered in Belgium and generates annual

combined sales of more than 4 billion. The 23000 employees around the world work together as

one company, serving customers in 120 countries.

Click Here For Card clothing � Details

Product description:

Product description:

- Bekaert offers a full range of card clothing products and auxilliaries for all fibre opening and carding applications:

- Plain rib and interlocking metallic card wires in a broad range of geometries, shapes, steel grades and finishes for all kind of applications

- Card wires for feed rollers, lickerin, transfer, fancy, cylinder, worker, stripper, doffer, condenser, randomizer, take-off� rollers

- Innovative SiroLock� wire design for workers and doffers

- Carding fillets for all types of cards and applications

- Unimech Advanced metallic wire mounting device for roller card applications

- Auxilliary items used in carding: gauges, portable microscopes, polishing stone, polishing sponges, hand cards for card wire stripping

- Comb blades

Carding solutions for non woven cards:

Advantages :

Carding solutions for non woven cards:

Advantages :

- Customized and innovative card wire solutions

- Superior quality card wire products resulting in excellent card performance

- Long lifetime of card wire

- Fast and dedicated service

Applications :

- Equipment

- Textile machinery

- Roller cards for nonwoven applications

- Nonwoven cards used for needled, spunlace, chemically bonded, thermally bonded nonwoven products

- Airlay cards for nonwoven applications

- Roller cards and opening equipment for fibre/textile recycling operations

For Further information kindly contact DEECO Group Or click on the above link for details

Air Layered Paper, Sanitary, Baby Care (EPS)

EPS, CHINA - Established in 1997 as First "Airlaid Paper Design Institute" in China, who first patented Composite Paper Production Line is basically manufacturer of complete Line (machinery) for Airlaid paper.

This company also has in-house manufacturing capacity of the paper products to supply to the user industry.

Product Made by EPS Air-laid production line and its Usages are:

- Latex-bonding paper:

Tablecloth, medical sheet, medical bag, salver pads, cup saucers, cushions, kinds of wet wipes for sterilizing, cleaning and caring skin, cosmetic face wipes and scarf etc.

- Thermal-bonding paper:

Sanitary towels, sanitary pads, baby diapers, medical sheet, incontinent mattresses, adult paper diapers.

- Multi-bonding paper:

Medical sheet, sanitary towels, sanitary pads, incontinent mattresses, salver pads, cup saucers, cushions, kinds of wet wipes for sterilizing, cleaning and caring skin, cosmetic face wipes and scarf.

- SAP Paper:

Sanitary towels, sanitary pads, baby diapers, medical sheet, incontinent mattresses, adult paper diapers.

- Spunlace Composite Product.

Supersede nonwoven cloth.

- Other special materials used in filter deodorization, electric materials, Airlaid production lines for Latex Bonding, thermal bonding.

Click

here to visit our website.

ROCOL

ROCOL has been creating lubricants with industry since the late 1870�s when the Ragosine Oil

Company pioneered the development and manufacture of performance lubricants from

conventional mineral oils. Throughout its history the company has continued to build and

enhance its reputation through the performance of its products.

Throughout industry ROCOL products are specified and used with the confidence achieved

through years of providing products that perform to the highest levels. Today the ROCOL brand

stands for superior performance, technical innovation and the highest standards of quality and

reliability, values which have been achieved through years and years of unswerving attention to

detail in the design and manufacture of products.

SCHOTT & MEISSNER

www.schott-meissner.de

Schott & Meissner was established by Heinz Schott and Wolfgang Meissner in 1986. Since then, the company name has been

a synonym for proven and reliable state-of-the-art Nonwoven Bonding Lines, Lines for Heat Treatment and Drying,

and Thermofix continuous Double Belt Presses.

We target potential customers who come up with specific process demands, which we can develop and offer reasonable

benefit-cost-ratio solutions for. Our machines and equipment also stand for notable return-of-capital-invest within

a short period of time.

Last but not least, Schott & Meissner also reflects the distinguished flexibility of a medium-sized

company and the utilization of modern manufacturing processes and systems to guarantee steady and consistent high quality standards.

Lines for Heat Treatment and Nonwoven Bonding

The root of our business is the heat treatment principle. We bring hot air, contact heat and radiant heat into shape, in order to dry,

melt or thermoset different kind of material in a continuous or discontinuous manner.

We are specialized on manufacturing Nonwoven Bonding Lines for thermal bonding by either low melt

fibers or melt powder as bonding agent, Chemical Bonding Lines for either spray application, foam impregnation or liquid binder bonding.

Downstream equipment such as calendars, accumulators and cut-to-length units do complement each of our line concepts.

Thermal Bonding/Nonwoven Bonding line.TopConLP Double Belt Air-Through Oven

TopConLP (LowPressure) means a Double Belt Compression Oven in modulardesign. Suitable for Nonwoven treatment

and Fiber bonding by means of convection-air-through-principle. Air draft can be arbitrarily set from bottom to

top or from top to bottom, meter per meter. After heating-up, the continuous web is cooled-down

by passing through a cooling zone, which also operates in air-through mode.

Additional features / oven upgrades available: Magnet System (to keep the upper belt in suspended position), Working Width Adjustment,

Belt Cleaning Device, Direct or Indirect Heating Systems (gas, thermo oil, steam), MultiFlow zone (for either heating or cooling), diversified peripheral

equipment...etc.

Technical Data

- Useful working width 1.200 - 6.000 mm

- Zone length 2.000 mm / 3.000 mm

- Free clearance between conveyor belts max. 300 mm

- Heating medium Natural gas, LPG, Hot oil, Steam, Electric energy

- Circulating air temperature max. 235o C

- Fiber PES, PP, PA, BiCo, Cotton, Shoddy, Regenerated Fiber, Flax, Hemp, Kenaf, Wood Fiber and Sheep Wool

- Weight range 20 - 8.000 gsm

- Density range max. 250 kg/m3

- Production speed max. 300 m/min

End Uses

- Upholstery for Furniture Industry

- Fiber fills and Interlinings for Apparel Industry

- Insulation material for Building and Automotive Industry

- Molding parts for Automotive Industry

- Filtration

- Geotextiles

- Medical application and Hygiene Industry

- Interlining

Double Belt presses.Thermofix Technology

Functional principle of Schott & Meissner's flatbed laminator Thermofix is a combination of contact heat and pressure.

The product to be processed is passed all through the machine by being hold in between two teflon-coated conveyor belts.

Heat transfer is by means of heating plates which are positioned right beneath top and bottom conveyor belts.

Additionally, the product can be passed all through one or multiple pairs of nip-rolls, arranged inline one after the other, as integrated

part of the flatbed laminator, whereas the product is still being hold in between the conveyor belts while being compressed by the calibrating rollers.

Subsequent to the heating zone, the flatbed laminator incorporates a cooling area. This field is for cooling the product down and to "freeze"

the achieved product features by means of cooling plates, which are also positioned right beneath top and bottom conveyor belts. A separate,

independent lifting unit which is connected to the cooling plates allows to cool and / or calibrate the product either with or without pressure.

Technical Data

- Useful working width 1.000 - 3.200 mm

- Free clearance between conveyor belts max. 200 mm

- Heating medium Hot oil (heated with natural gas), LPG,Electric Energy

- Operating temperature max. 240oC

- Zone length Heating / Cooling 1.000 mm, 2.000 mm, 3.000 mm

- Production speed max. 25 m/min

End uses

- Production of sandwich panels / Composites (eg.: Automotive Industry - side walls, trailor superstructures,

ground plates, car interiors, insulation panels, etc.)

- Production of Honeycomb Panels / Composites (eg.: Automotive Industry - side walls, ground plates,

car interiors, elements for sound absorption, etc.)

- Thermal consolidation, eg.: TWINTEX or fiber glass with PP

- Thermal consolidation of scattered goods (z.B. PVC granules to flooring goods)

- Thermal consolidation of multiple textile layers (eg.: interlinings)

- Thermal consolidation of fiber-reinforced plastics (vehicle underbodies)

- Thermal consolidation of recycled material to insulation panels or molded parts (e.g.: wheel-houses)

- Thermal lamination of multiple layers, such as fabric, foil or foam (e.g.: headliners)

The SCHOTT & MEISSNER also offer wide range CAPITAL EQUIPMENT for TECHNICAL TEXTILE,

- Surface Coating Lines Coating Systems Dry Coating Systems

- Winding Systems Ascending Batch Winders Center Winders Automatic Winders

- Palletizer

Main

Main Non Woven

Non Woven