Wool Worsted Spinning

Tow to Top Conversion

Non Woven

Waste Recycling

Cotton and Synthetic

Spinning

Spinning

Man Made Fibre Processing

Yarn Carriers/Dye Tubes

Technical Textiles

Lamination and Coating

Lamination and CoatingSpun & filiature Silk

Lubricants and greases for all textile machines

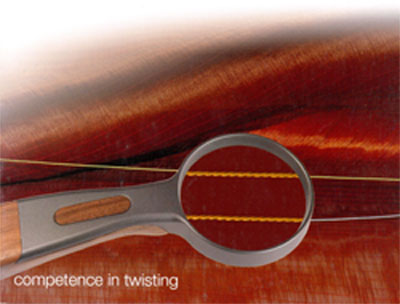

Twisting

Weaving

Benninger Zell GmbH

Engineering Plant &

Machinery

Machinery

Health Care - Sanitary, Baby

Care

Care

Films

Bailing and Bump press for Spun fibre

Reeling machine for Spun and Filament

Soil Mechanics

Combustion Catalyst for Liquid & Solid Fuels - GreenTech

Lamination and Coating

Lamination and CoatingLaminating Coating Machines - HIP MITSU

www.hip-mitsu.com/home/

Hip-Mitsu s.r.l., located near Venice, Italy is one of the leading producers of Hot Melt coating and laminating machines, systems and equipments for hot melt adhesives. Hip-Mitsu have more than 2,000 installations in 38 Countries all over the world covering the most diverse industrial fields.

Hip-Mitsu Hotmelt Laminating and Coating machines work with 2 applications systems - Slot Die and Spray Gun System and can process almost all the hotmelt adhesives such as EVA, Pressure Sensitive PSA , PA, PO, Reactive PUR, UV curable, acrylic based.

The key features of their application systems are:

The application range includes coating, laminating, self-adhesive and thermo-adhesive products.

Coating :

Laminating :

The range of substrates in form of roll goods and in sheet, of any thickness, include textile (woven, knitted, stretch), nonwoven, foam, foil, paper, plastic film, breathable plastic film (membrane, tissue) etc.

Product range possible to produce on the system: hygiene, medical, automotive, technical membrane, roofing, technical textiles, filtration media, interlining, foam converting, sportswear, buildings (insulation), home furnishing, mattress ticking, reinforcing membrane, insulation

The Slot Die System from Hip-Mitsu have added advantages such as :

HIP-Mitsu also offer following systems/conversions and peripheral quipments:

At Hip-Mitsu they have a state-of-art Competence Center, equipped with the most advanced technologies and production lines where trials of the material can be conducted with all types of polymers and adhesives.

Hip-Mitsu s.r.l., located near Venice, Italy is one of the leading producers of Hot Melt coating and laminating machines, systems and equipments for hot melt adhesives. Hip-Mitsu have more than 2,000 installations in 38 Countries all over the world covering the most diverse industrial fields.

Hip-Mitsu Hotmelt Laminating and Coating machines work with 2 applications systems - Slot Die and Spray Gun System and can process almost all the hotmelt adhesives such as EVA, Pressure Sensitive PSA , PA, PO, Reactive PUR, UV curable, acrylic based.

The key features of their application systems are:

- Coating weight application ranges from: 0.02 to 1500 gsm

- Processing speed: 2 mts./min. to 900 mts./min

- Processable hotmelt adhesives application width ranges from 0.3 mm to 6000 mm

- Wide range of Viscosity from 100 to 120,000 mPass

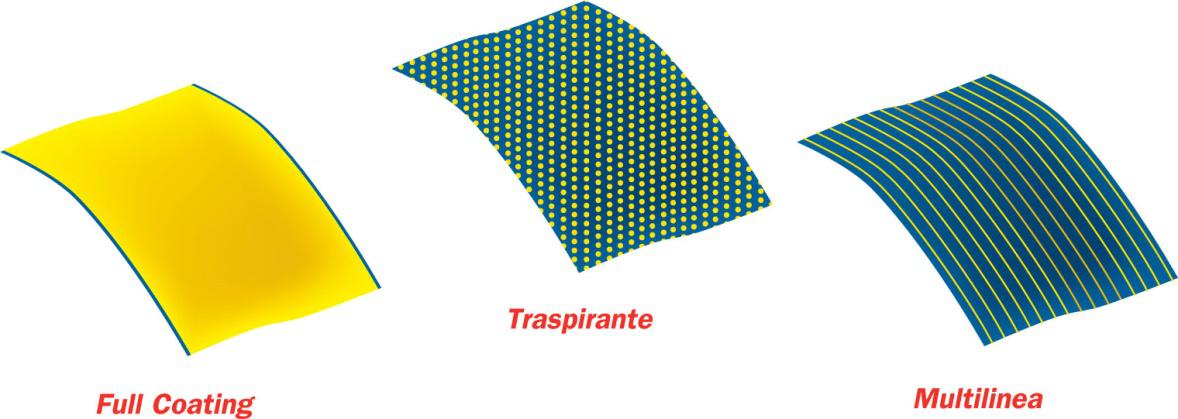

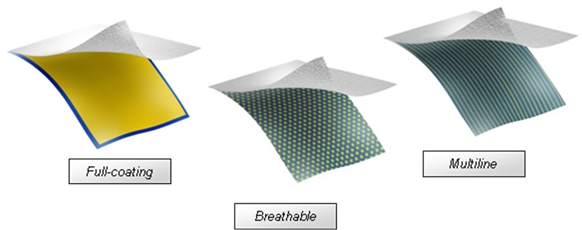

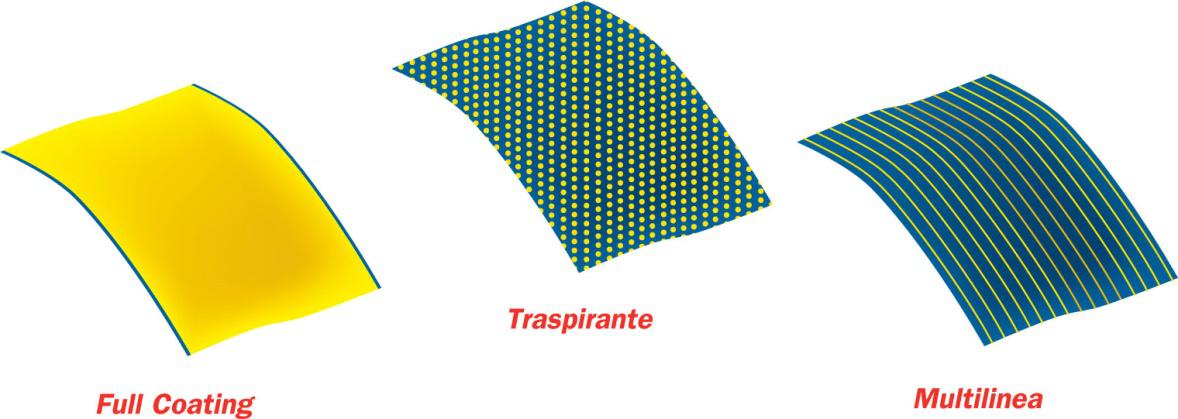

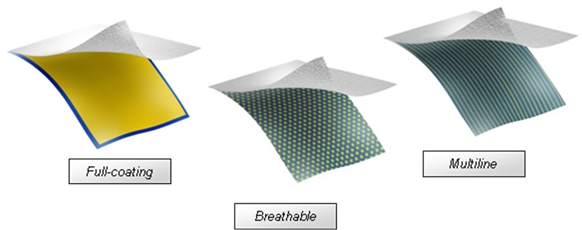

- Possible coating : Full coating, breathable (open) coating structure, multi-line coating or intermittent coating

The application range includes coating, laminating, self-adhesive and thermo-adhesive products.

Coating :

Laminating :

The range of substrates in form of roll goods and in sheet, of any thickness, include textile (woven, knitted, stretch), nonwoven, foam, foil, paper, plastic film, breathable plastic film (membrane, tissue) etc.

Product range possible to produce on the system: hygiene, medical, automotive, technical membrane, roofing, technical textiles, filtration media, interlining, foam converting, sportswear, buildings (insulation), home furnishing, mattress ticking, reinforcing membrane, insulation

The Slot Die System from Hip-Mitsu have added advantages such as :

- Extreme flexibility in case of running small production batches

- No pressure during application of adhesive so no penetration of adhesive in carrier substrate resulting into great softness and hand-feel of final product

- Simple and quick change of adhesive application weight without changing any mechanical changes resulting into no downtime, reduced costs and minimum manpower requirement

- Application weight accuracy is quite precise both in cross and machine direction

- Easy cleaning of the slot die application system

HIP-Mitsu also offer following systems/conversions and peripheral quipments:

- Retrofit of their systems / equipments on customers (other) existing machines

- Conversion triplex laminating

- Melters-melting tanks and drum melters for hotmelt adhesives

- Thermo controller hoses for hotmelt system

- Narrow / pilot width coater upto 100 mm width and plot unit of Coating / laminating with roller application system of 500 mm width

- Triplex laminating system with 2 application heads or conversion

At Hip-Mitsu they have a state-of-art Competence Center, equipped with the most advanced technologies and production lines where trials of the material can be conducted with all types of polymers and adhesives.

Twisting Systems & Solutions - Oerlikon Saurer Allma product lines, Germany

DIETZE + SCHELL (Special Purpose Machines for Textile, Plastics and Glass fibre Industry)

SIKA

Texmer GmbH & Co. K.G